Komatsu PC600 Excavator Undercarriage Spare Parts - Professional

Heat-treated Track Bottom Roller 9109493

1. What is a track roller?

Track rollers serve as the undercarriage’s load-bearing backbone, tasked with supporting the bulldozer’s full weight, absorbing

severe ground shocks, and contributing to over 70% of operational resistance—a non-negotiable role in machinery performance.

For track and carrier rollers, materials like 40Mn2,40MnB,50Mn are selected based on working conditions. Through precision

forging and subsequent heat treatment, the rollers achieve HRC52-60 surface hardness and a 7-10mm hardened layer depth (HRC45), ensuring high impact resistance and wear durability on their

contact surfaces. Equipped with high-quality floating seals and a

reliable lubrication system, they operate seamlessly in extreme

climates ranging from -45℃~120℃ with minimal maintenance requirements.

Our Track Rollers feature a unique welding-before-CNC-machining

process on vertical lathes, eliminating concentricity errors and

significantly reducing rapid wear issues. This craftsmanship

ensures superior operational stability and extends the service life of the products, delivering unmatched quality in heavy-duty applications.

2. Engineering Excellence: Why Our Track Rollers Dominate Severe

Conditions

✅ Military-Grade Sealing Integrity

Each roller undergoes rigorous 0.6 MPa (6 bar) high-pressure gas

testing – 60% beyond industry standards – to guarantee zero-leak reliability in extreme conditions. This

critical QC process eliminates oil seepage at the source through

advanced sealing technology. Validated via accelerated wear

simulations, the assemblies deliver >3,000-hour operational lifespans despite constant immersion in abrasive mixtures (e.g., silica-rich

mud, granite slurry) and dynamic stresses from rock impacts. The

result: field-proven resilience that slashes maintenance costs.

✅ Forged Alloy Armor Defense

Precision metallurgy for extreme environments:

Surface Shield: 60-65 HRC hardness → Crushes wear

Structural Core: 450MPa+ tensile strength → Defies impacts

Shaft Defense: Triple chrome plating → Outlasts corrosion

✅ Battle-Proven Load Capacity

Engineering breakthroughs eliminating failure modes:

✓ 30% optimized load distribution → Neutralizes stress concentrations

✓ Reinforced raceways/bearings → Prevents flange wear & bending

✓ Sustained cyclical load endurance → Slashes downtime, boosts longevity

3. The Cost-Smart Solution for Mining & Heavy Earthmoving

End Excavator Downtime: Conquer Rock & Slash Costs

Problem (Pain Points):

❌ Rollers Shatter Prematurely on rock-strewn terrain

❌ Spiraling Repair Bills eating your profits

❌ Profit-Killing Breakdowns crippling productivity

Solution (Our D10 Rollers):

✅ 22% Fuel Savings

Advanced low-resistance design cuts operating costs

✅ Seamless Komatsu Fit

Direct OEM replacement = zero installation headaches

✅ 3X Lifetime vs Standard

*Premium alloys + 3-Year Structural Warranty*

✅ >3,000-Hour Durability

Proven in granite slurry & high-impact conditions

Closing Hook:

Stop Losing Money to Weak Rollers

Protect Your Investment → Maximize ROI

Unstoppable Traction & Uptime Start Here:

Factory-Direct Pricing | ISO 9001 Certified Quality | Global

Logistics Network

4. Production Processes

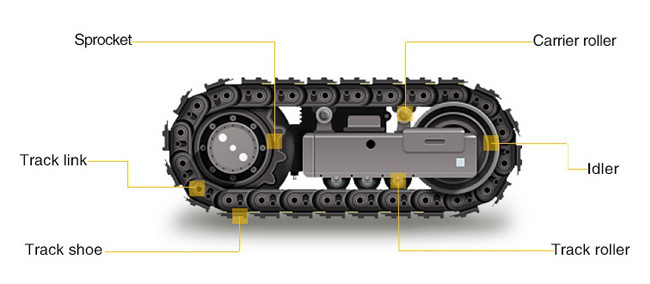

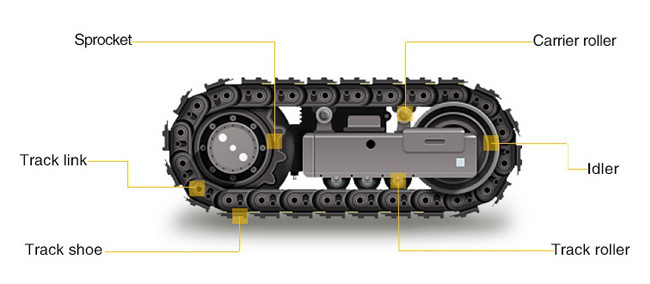

5. Track Roller Structure

6. Design/Structure/Main Dimensions of Installation

7. Our Advantages

* World-class quality

* Factory sale directly with reasonable price

* 35 years experience in Excavator & Bulldozer spare parts

manufacturing

* Flexible payment terms including T/T, L/C and so on

* Fast delivery within 30 days after contract established

* Professional sales team, quality inspection, and report, maritime

logistics guidance

* After-sale services: video technical support,24h online support

8. Hot Sale Products