Single Flange Bulldozer Undercarriage Spare Parts Forging Track Bottom Roller

1. What is a roller?

The roller, a crucial component within engineering machinery

chassis conveyors, exhibits diversity in types and substantial

quantities, effectively supporting the conveyor belt and the load

of transported materials. Representing 35% of the overall

conveyor's cost, it generates over 70% of the resistance

encountered. Hence, the quality of the roller is of utmost

importance. These rollers are manufactured using two primary

materials: steel and plastic.

2. Track Rollers Excavator Features

* Employing quench-hardening treatments, our engineering machinery

chassis components achieve superior mechanical properties, high

tensile strength, and exceptional resistance to bending and

fracture.

* Featuring a surface hardness range of HRC40-55, these components

exhibit reduced wear and extended service life, thereby enhancing

the durability of your products and ultimately adding value to your

business.

* Precisely engineered and meticulously crafted, our chassis

components ensure secure and reliable fixation. They are capable of

accommodating heavy loads up to 50 tons without compromising the

operational efficiency and reliability of the excavators. Offering

cost-effectiveness, high-quality services, and exceptional

performance, our products represent the optimal choice for your

needs.

3. Production Process

4. Main Dimensions of Installation

MAIN PARAMETERS

| Brand | Model | Main Dimensions of Installation |

| A | B | E | G | M | L |

| Bulldozer Series | D20 | 155 | 135 | 130 | 264 | 194 | 15 |

| D3C | 178 | 152 | 155 | 274 | 230.5 | 13.5 |

| D30 | 198 | 170 | 154 | 285 | 240 | 17.5 |

| D31 | 198 | 170 | 154 | 285 | 240 | 17.5 |

| D4 | 230/219 | 203 | 174 | 358.5 | 298 | 17 |

| D4D | 230/219 | 203 | 174 | 358.5 | 298 | 17 |

| D5 | 233 | 204 | 208 | 369 | 317.5 | 17 |

| D6D | 246 | 210 | 228 | 400 | 330.5 | 20.5 |

| D7 | 256 | 222 | 248 | 439.5 | 368.3 | 20 |

| D7G | 256 | 222 | 248 | 439.5 | 368 | 245 |

| D8K | 300 | 280 | 296 | 533.6 | 428.6 | 27 |

| D40 | 233 | 204 | 208 | 308 | 310 | 18 |

| D50 | 233 | 204 | 208 | 380 | 310 | 18 |

| D60 | 245 | 210 | 235 | 394 | 320 | 19 |

| D65 | 245 | 210 | 235 | 394 | 320 | 19 |

| D80 | 258 | 220 | 252 | 452 | 380 | 23.5 |

| D85 | 258 | 220 | 252 | 452 | 380 | 23.5 |

| D155 | 296 | 258 | 292 | 498 | 408 | 26 |

| 300907 | 188 | 162 | 138.5 | 242 | 212 | 13 |

| ECM440 | 188 | 162 | 138.5 | 242 | 212 | 13.5 |

| T90 | 2160 | 185 | 213 | 351.4 | 298 | 18 |

The models above are just for reference, many models we can't list

here.we can supply more products as your requirement. Please feel

free to send us your inquiry or email if you have any requirements.

5. Other Advantages

* World-class quality

* Factory sale directly with reasonable price

* 35 years' experience in Excavator & Bulldozer spare parts

manufacturing

* Flexible payment terms including T/T, L/C and so on

* Fast delivery within 30 days after contract established

* Professional sales team, quality inspection and report, maritime

logistics guidance

* After-sale services: video technical support, 24h online support

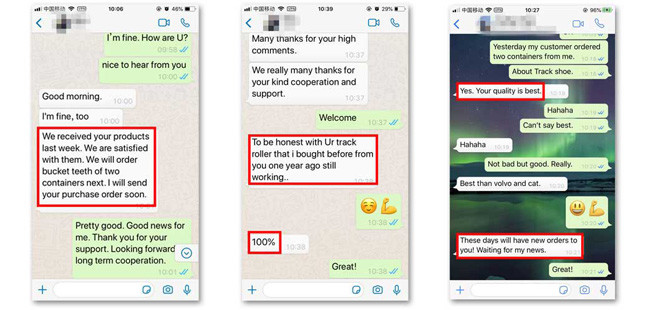

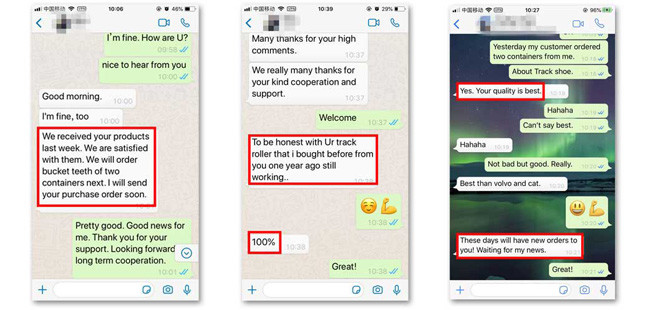

6. Customer Feedback

Are you still troubled by lacking of quality excavator track

roller? YinTai Parts is one of the professional manufacturers and

suppliers of excavator track roller in China, who has high quality

products for sale. With over 30 years experience and wide

expertise, we can assure you the high quality and good performance

of our products.